- Who We Are

To provide value-adding solutions that reduce operating costs, maximise performance, and extend asset life. We achieve this by applying holistic, responsive engineering solutions at every stage of an asset’s life cycle, and by staying true to what makes us unique: precision, collaboration, trust, and experience.

Having built a reputation for excellence on the back of two generations of family passion; at Berg our team is our family. We know their kids, their parents, their personal legacies. What’s more, we all work together.

Our reputation for on time and on budget delivery is what sets Berg apart from our competitors and with our industry leading facilities in our Brisbane, Gladstone and New Caledonia workshops, Berg can comfortably deliver contracts up to $15 million in value.

We provide a culturally safe environment for our staff and communities through recognition of our first peoples.

High school students have toured Berg’s Brisbane site to learn more about a career in manufacturing and welding.

Headquartered in Brisbane and with bases in the Asia Pacific we strive to provide our clients with intelligent asset lifecycle management solutions that reduce operating costs, maximise performance and extend asset life; all the while ensuring we meet our ISO accredited quality, environmental and safety standards.

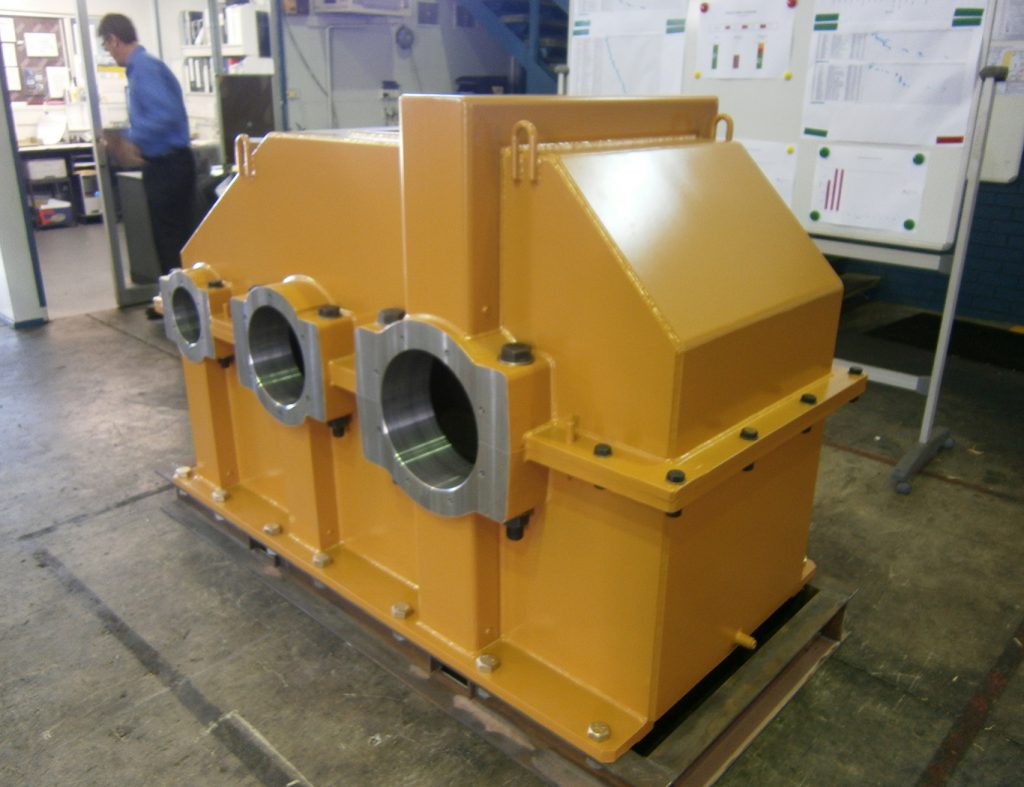

- What We Do

Berg have invested more than $5million to acquire and house the state-of-the-art Titan SC 40/50-4HY Double Column Vertical Boring & Turning Mill.

- Who We Service

Berg Engineering has provided engineered rail solutions for over 51 years and continues to be a single source provider for all types of machined components.